- +45 54 60 90 06

- Østervej 2, DK-4960 Holeby, Denmark

- info@coolmachineseurope.com

IWS Brochure

IWS Brochure

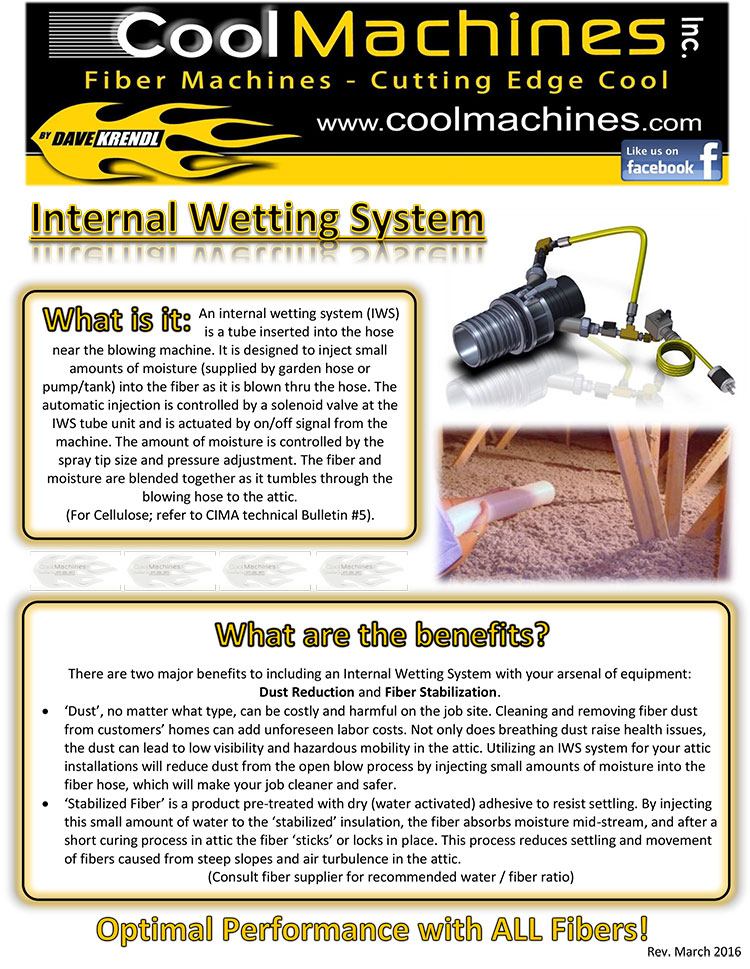

Wetting System

An internal wetting system (IWS) is a tube inserted into the hose near the blowing machine. It is designed to inject small amounts of moisture (supplied by garden hose or pump/tank) into the fiber as it is blown thru the hose. The automatic injection is controlled by a solenoid valve at the IWS tube unit and is actuated by on/off signal from the machine. The amount of moisture is controlled by the spray tip size and pressure adjustment. The fiber and moisture are blended together as it tumbles through the blowing hose to the attic.What are the benefits?

There are two major benefits to include an Internal Wetting System with your arsenal of equipment,

1. Dust Reduction

2. Fiber Stabilization

“Dust” no matter what type, can be costly and harmful on the job site. Not only does breathing dust raise health issues, the dust may lead to low visibility and hazardous mobility in the attic. Using the IWS system for your attic jobs will reduce dust from the open blow process by injecting small amounts of moisture to the fibers, which will make the job cleaner and safer.

“Stabilized fiber”, by injecting small amount of moisture to the fiber reduces the settling and movement of the fibers and thereby reduce the settling process in the loose fibers.